From Layout to Distribution: Mastering the Art of T-Shirt Screen Printing

The trip from design to delivery in t-shirt screen printing includes a collection of essential stages that demand interest to information and strategic planning. It starts with recognizing the nuances of your target audience, adhered to by the option of appropriate materials and the prep work of art work that satisfies high criteria. Yet, as the process unfolds, difficulties in quality assurance and logistics can emerge, possibly impacting the final result. Exploring these intricacies discloses not just the details of screen printing yet additionally the important practices that can elevate a brand's standing in a competitive market.

Comprehending T-Shirt Screen Printing

Recognizing T-Shirt screen printing involves identifying a versatile and commonly made use of method for moving styles onto textile. This strategy utilizes a pattern and a mesh screen to apply ink onto numerous fabric materials, mostly cotton and polyester blends. The process starts with the development of a screen that includes the wanted layout, which is then thoroughly aligned on the textile.

Ink is pressed with the screen's open areas making use of a squeegee, enabling exact application of shade. This method is preferred for its capability to produce vivid, durable prints that hold up well to washing and put on. In addition, screen printing is capable of accommodating both straightforward and intricate designs, making it a recommended selection for personalized garments, advertising items, and also creative jobs.

In addition, screen printing supplies scalability, making it ideal for both little batch orders and massive productions. While preliminary arrangement costs might be higher contrasted to various other printing methods, the performance and durability of screen printing usually justify the financial investment. Overall, comprehending the fundamentals of Tee shirts screen printing is essential for any individual aiming to take part in this preferred form of textile design, whether for business ventures or individual jobs.

Conceptualizing Your Style

Conceiving your layout is an important action in the Tees screen printing process, as it sets the structure for the whole project (Screen Printing). This stage involves producing concepts that resonate with your target market while ensuring that the layout aligns with the brand name's identity and message. It is important to start by discovering themes, color pattern, and graphics that show the desired aesthetic

Sketching preliminary ideas can be beneficial, enabling a graph of concepts before completing the layout. Think about the usage of typography, imagery, and layout in a means that records focus and connects effectively. Furthermore, it is crucial to expect the printing technique that will be employed, as this can affect layout intricacy and shade selections.

Taking part in conceptualizing sessions with staff member or looking for responses from possible consumers can additionally enhance the conceptualization process, giving diverse viewpoints that refine the layout. Eventually, a well-balanced style not only enhances the aesthetic allure of the Tees yet additionally cultivates a link with the target market, driving rate of interest and potential sales. Devoting time to conceive your design can lead to a successful screen printing outcome.

Choosing the Right Materials

The weight of the fabric, typically gauged in grams per square meter (GSM), affects the drape and total feel of the T-shirt. Larger fabrics might give a more premium appearance, while lighter choices are comfy for casual wear. Texture also contributes; smoother textiles tend to yield sharper prints, while distinctive surface areas can develop special aesthetic impacts.

Furthermore, think about the environmental impact of materials. Organic cotton and recycled polyester are acquiring popularity among eco-conscious consumers. Inevitably, picking the ideal materials involves balancing aesthetic appeal, functionality, and sustainability, guaranteeing that the T-shirt not only looks terrific yet additionally fulfills the assumptions of your target market.

Preparing Artwork for Printing

Preparing art work for T-shirt screen printing requires mindful attention to information to ensure that the last print precisely shows the designated style. The very first step is to develop a high-resolution electronic file, preferably in vector style, as this enables scalability without loss of high quality. Common software program utilized for this objective includes Adobe Illustrator and CorelDRAW.

Next off, validate that all text is converted to outlines or rasterized to prevent font issues during printing (Abilene T-Shirt Screen Printing Company). Additionally, it is vital to validate that the color setting is readied to CMYK, as this aligns with the printing procedure. Pay close interest to shade matching; utilizing Pantone colors can assist achieve uniformity across various prints

Take into consideration the dimensions of the print location and maintain correct margins to prevent design cutoff. It's additionally smart to include registration marks for placement during the printing process. Screen Printing. Request a proof from the printer to picture the final item before mass manufacturing. This action is important for identifying any prospective concerns, ensuring that the printed T-shirt satisfies the wanted quality and style requirements. Correct preparation of art work greatly affects the total success of the screen printing project

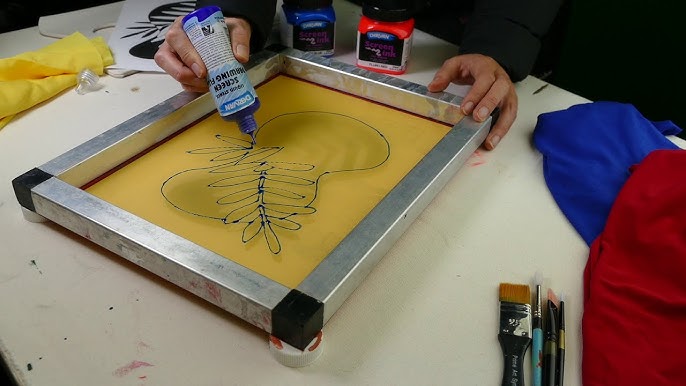

Understanding the Printing Process

Understanding the printing procedure is essential for achieving top notch outcomes in Tees screen printing. This stage entails numerous significant steps that directly influence the final product. The primary step is establishing the printing press accurately. Proper registration of screens assurances that colors align correctly, stopping misprints and assuring a specialist look.

Next, choosing the appropriate ink is very important. Various ink kinds, such as plastisol or water-based, offer various surfaces and longevity. Comprehending the fabric make-up of the Tees likewise helps in picking suitable inks.

When it involves the real printing, regulating the squeegee stress and angle is essential. Regular stress will yield even ink distribution, while the angle affects the flow and insurance coverage. In addition, adjusting the rate of the printing machine can affect the ink's healing process, which is fundamental for assuring toughness.

Quality Assurance and Finishing

After the printing procedure is total, executing effective high quality control measures comes to be important to validate that each Tee shirts meets the desired criteria. Quality assurance involves a systematic approach to inspecting each garment for issues, confirming that the print top quality, color precision, and fabric stability align with the requirements set throughout the design stage.

The very first step in quality assurance is a detailed visual evaluation. This requires monitoring for usual issues such as misalignment, ink spots, or fading. Any kind of T-shirt that does not satisfy the quality criteria should be dealt with promptly, either through reprinting or repair service.

Along with visual checks, it is important to carry out clean tests on a sample of printed t shirts to evaluate the longevity of the inks and the overall durability of the design. These tests aid validate that the print will preserve its vibrancy webpage and stability after multiple laundries, a vital element for consumer contentment.

Completing touches, such as thread trimming and the application of care labels, additionally play a considerable role in top quality control - T-Shirt Printing. By concentrating on these facets, services can enhance the total discussion of their products, ultimately resulting in a much more enjoyable client experience

Product Packaging and Shipment Solutions

To accomplish excellent packaging, take into consideration using green materials that line up with sustainability fads, such as recyclable poly bags or biodegradable boxes. Each Tee shirts should be neatly folded up and put in safety wrapping to stop creasing and potential damage throughout transit. Consisting of a branded insert or treatment directions can better personalize the experience, promoting client commitment.

Picking a dependable delivery companion is vital when it comes to delivery. Assess alternatives based on monitoring, speed, and cost capacities. Providing numerous delivery approaches can provide to various client requirements, from common to expedited shipping.

Frequently Asked Questions

What Are the Usual Blunders Novices Make in Screen Printing?

Common blunders novices make in screen printing include incorrect screen prep work, inadequate ink blending, inaccurate direct exposure times, not enough curing, and neglecting to examine prints. These errors can lead to low quality and disappointing lead to last products.

How Can I Stop Ink From Bleeding Throughout Printing?

To avoid ink bleeding throughout printing, assurance proper screen tension, use appropriate emulsion thickness, select the appropriate ink uniformity, preserve excellent healing temperature levels, and prevent overloading the screen with excessive ink during application.

What Types of Inks Are Best for Different Fabrics?

Selecting inks based upon material type is vital. Water-based inks are perfect for cotton, giving soft qualities. Plastisol inks suit artificial materials, providing resilience. Release inks efficiently mix with natural fibers, ensuring dynamic shades without endangering textile integrity.

Exactly how Do I Pick the Right Screen Mesh Count?

Selecting the appropriate screen mesh count depends on the desired print information and ink type. Abilene T-Shirt Screen Printing Company. Greater mesh matters generate better information, while reduced matters facilitate thicker inks. Analyze textile kind and style intricacy for excellent outcomes

Can I Utilize Screen Printing for Tiny Set Orders?

Yes, screen printing can be efficiently made use of for small batch orders. This technique enables premium outcomes and thorough layouts, making it a viable option for custom-made garments, promotional products, or minimal edition runs.

Comprehending T-Shirt screen printing includes identifying a versatile and commonly made use of technique for moving designs onto textile. While initial configuration prices may be higher contrasted to various other printing techniques, the effectiveness and durability of screen printing commonly warrant the investment. Preparing artwork for T-shirt screen printing needs cautious interest to information to ensure that the last print properly mirrors the intended design. Mastering the printing process is vital for attaining top notch outcomes in Tee shirts screen printing. Typical errors novices make in screen printing consist of inappropriate screen preparation, insufficient ink mixing, incorrect exposure times, insufficient treating, and ignoring to check prints.